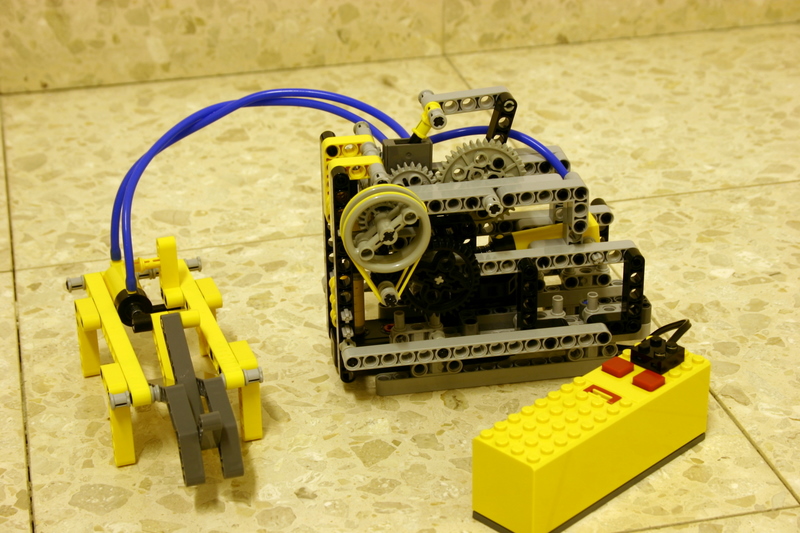

A video of the mechanism in action (14MB)

This structure demonstrate a technique that allows you to use one motor to do two things:

In this construction the motor is a stand-alone motor (the RC Buggy motor), but a motor controlled by a NXT or an RCX can also be used, of course. The idea is quite simple. The compressor provides air pressure no matter which direction the motor rotates. So by coupling the motor to a pneumatic switch, we can flip the switch either way (but not to the center, but flipping all the way is usually sufficient).

My model is quite big and as you can see in the picture and the video, I needed to brace it quite heavily. This is due to two things. First, I am using the hand pump, which is large and hard to operate. Second, the pneumatic switch is also fairly hard to operate, so it needs high torque, but it also serves as a mechanical limiting mechanism. Once it reaches the end of its travel, the gears that move it can't rotate, and the rubber bands that run them slip. (the clutch gear also works, but not as well). So on one hand we need high torque to flip the switch, but on the other the slipping mechanism can only provide a little bit of torque. So we need to gear down a lot.

I believe that the mechanism can be simplified and made smaller, but it probably won't get really compact. Using a smaller motor and the small pumps would certainly help.

© 2006, Sivan Toledo